Project:

Sandford Compound – Hinkley Point OHL Scheme

Location:

Mendip Hills

Client:

National Grid, on behalf of Balfour Beatty

Area Covered:

14,100m2

Solution:

SUREGROUND™ Reversible Soil Enhancement System

Testimonial:

“On the Hinkley Connection Project we continually strive to find better ways of doing things. SUREGROUND™ by Soil Science Ltd is a more sustainable engineering solution for haul roads and laydown areas. It means fewer lorry movements, less vehicle-related emissions and a reduction in the quantity of aggregate transported onto site. Fitting the sustainability agenda, it delivers the best results for our customers, the local community and the environment and makes good business sense.”

Matthew King, SHESQ Manager

National Grid

The Challenge

As part of the 400kV Cable works on National Grid’s Hinkley Connection Project, a temporary compound and haul road was required to enable the construction of Sandford Substation. The initial design required stripping of topsoil and laying a stone hardstanding utilising a geosynthetic system. Poor ground conditions meant that stone thickness would be in excess of 500mm and a larger area for the storage of subsoil would be required.

The Measures

Over the course of 18 months, the Balfour Beatty project team have worked in conjunction with Soil Science Limited to identify a sustainable alternative that would eliminate the need to import large quantities of aggregate to site and reduce the size of a soil storage area required.

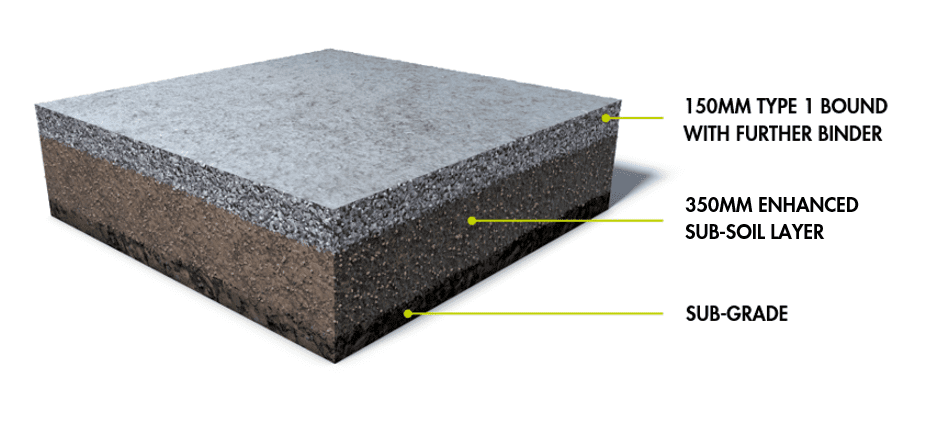

This alternative came in the form of SUREGROUND™ Reversible Soil Enhancement System which mixes in-situ site soils with a proprietary binder. This stabilises the subsoil and increases the load bearing capacity of the ground.

A summary of the process for implementing SUREGROUND™ at Sandford Compound was as follows:

- Extensive testing of the subsoil confirmed the nutrient composition of the subsoil and determined the amount of binder required to stabilise the area.

- Following topsoil strip, the top 300mm of the subsoil was rotavated with SUREGROUND™ binder and compacted.

- Stabilised subsoil was then capped with a Surface Armouring layer of stone bound together with the SUREGROUND™ binder.

The Results

In comparison to traditional stone construction methods, SUREGROUND™ provides the following benefits:

- 11,000 tonnes of aggregate were designed out as no longer required;

- Overall 66% reduction in vehicle movements;

- Eliminates use of geosynthetics which would otherwise result in large volumes of plastic waste that cannot be recycled;

- Installation time was halved;

- Approximately 142 tonnes of CO2 emissions have been prevented;

- Healthy community relationships were maintained by reducing vehicle movements on the local road network and associated noise, dust and vibration levels; and

- Area of works can be fully decommissioned with subsoils returned to their natural state in line with DEFRA pH and nutrient indices.

This case study was kindly provided by Richard Sanderson, Project Manager, Balfour Beatty.

- Programme Reduction 50%

- Vehicle Movements Reduction 66%

- Associated Carbon Emissions Reduction 67%

- Imported Aggregate Reduction 66%

- Material sent to landfill reduced by 100%

- Stone Layer depth reduction 70%

- Programme Reduction 50%

- Vehicle Movements Reduction 66%

- ASSOCIATED CARBON EMISSIONS REDUCTION 67%

- Imported Aggregate Reduction 66%

- Material sent to landfill reduced by 100%

- Stone Layer depth reduction 70%

Get in touch

For further information about our services, please call us on 0118 3389 530 or

As used by